Performance not only defines growth trajectories but also long-term sustainability, building a strategic sector for the development of a country

The metalworking industry has already achieved 100% recovery from the effects of the coronavirus pandemic. covid 19thus offering its services to other important economic sectors of the country.

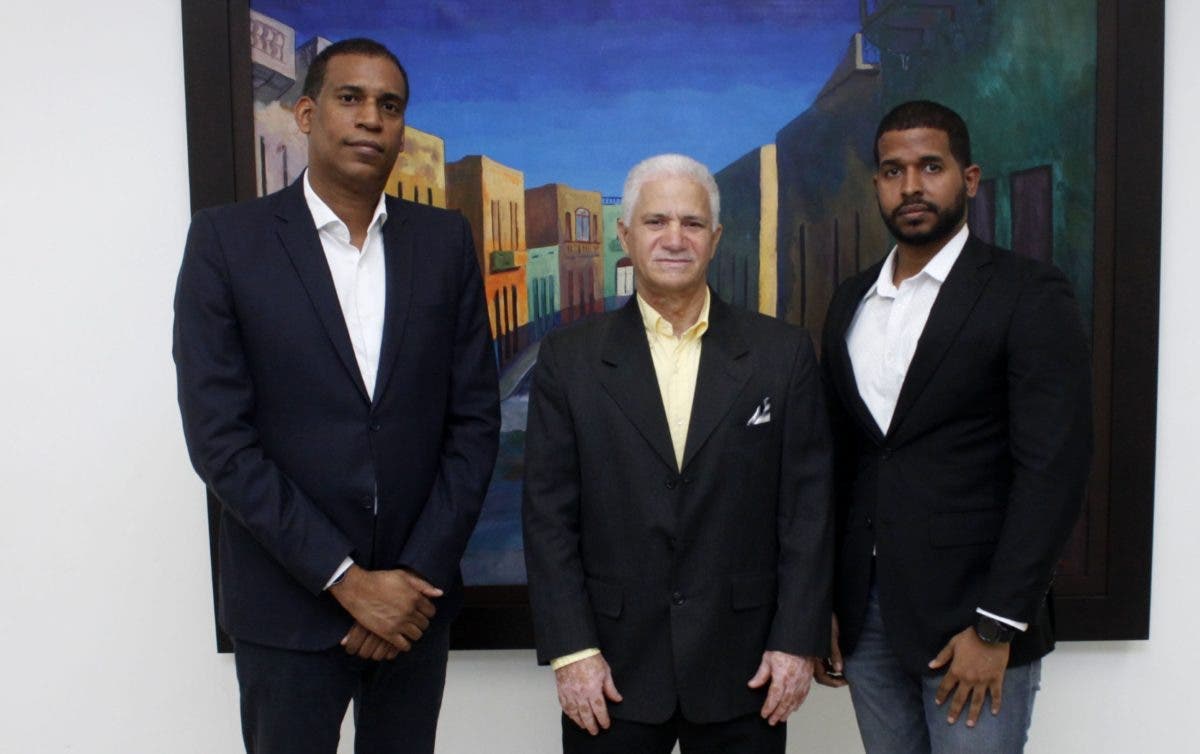

By participating in the TODAY Economic Meetingthe directors of the National Association of Metalworking and Metallurgical Industries (Asonameca), Ándrés Arias MejíaPresident; Jesus Nunez Grullon and Jose Cuevasmembers, stressed that without the metalworking industry a country does not develop, because it is the one that provides machinery and inputs to most economic activities for its reproduction, among them, the manufacturing industry, construction, automotive complex, mining , agriculture, among others.

In this way, the sector has a decisive influence on the process of material reproduction of the economy. Therefore, its performance not only defines growth trajectories but also its long-term sustainability, building a strategic sector for development.

They also highlighted that for every 100 jobs generated by the industrial sector, metalworking contributes eight, according to a survey that was carried out at the request of the Ministry of Industry, Commerce and MSMEs.

They also stated that this industry has managed to finance its modernization through the Business Cooperative and the National Council for the Promotion and Support of Micro, Small and Medium Enterprises (Promipyme).

In that sense, they added that the metalworking industry in the Dominican Republic is up-to-date at a technological level.

We invite you to read: Fipetur defines the DR as a world reference in tourism management in times of crisis

They mentioned that in the country there are companies in this sector that have water jet and laser cutting machines, with numerical control of four and five axes.

They emphasized that the Business Cooperative is the “strong arm” of Asonamecawhich last year disbursed more than RD$100 million for the purchase of technology.

They explained that for two years that cooperative has had a soft loan plan that has allowed the installation of modern equipment and machinery. They indicated that through Promipyme they have also obtained important financing at competitive rates of 8%.

However, they regretted that obtaining financing from commercial banks for the purchase of equipment and machinery for the industry is more expensive than to acquire a vehicle for personal use.

In addition, for the directors of Asonameca, covid 19 left the challenge of carrying out exchanges with countries that have a more developed metalworking industry than the local one in order to acquire more knowledge.

They announced that a manufacturing fair is being prepared in Chicago, United States, in which members of Asonameca traditionally participate.

Lack of skilled labor

One of the main challenges that the metalworking industry currently faces is obtaining qualified labor.

The president of the National Association of Metalworking and Metallurgical Industries (Asonameca), Ándrés Arias Mejía, attributed the situation to the fact that currently most young people have been more inclined to study information and communication technology than hard technology, as is metalworking, which requires a lot of hand skills and concentration.

He said that this is causing the lack of turners, presses and foundrymen for that industry. He revealed that in order to face this lack of qualified labor, Asonameca has been in conversation with the National Institute of Professional Technical Training (Infotep) with the aim of relaunching the Dual Training Program and thus promoting industry 4.0.

He added that this provides for the incorporation of metalworking, emphasizing that without this industry there is no development anywhere in the world.

He said that they will also be offering talks in high schools to motivate students to train in the area of metalworking.