We are more than accustomed to recycling our domestic waste. In Spain, for example, Millions of tons of containers are managed every year. But did you know that buildings and their materials can also be recycled? Moreover, did you imagine that a building can be completely disassembled and remembered?

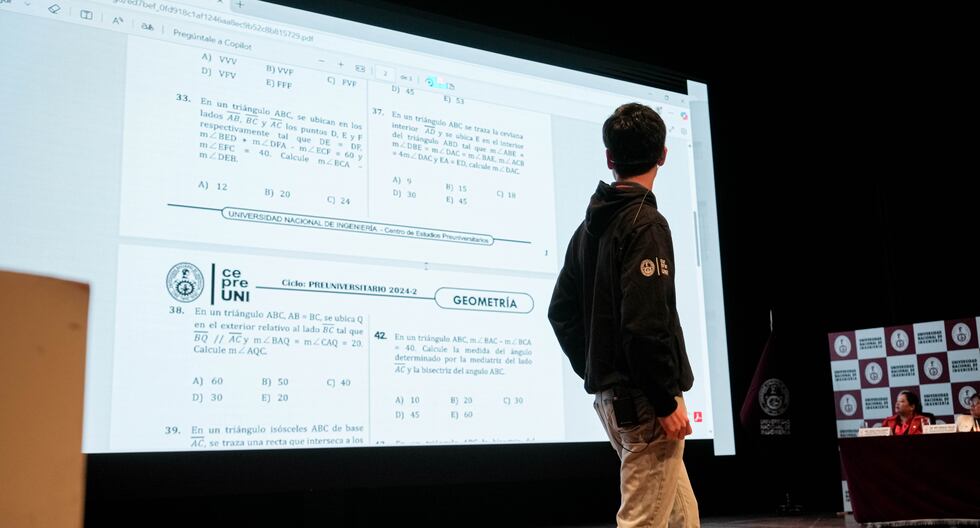

Formula 1, often innovations laboratory, offers us a tangible example: “Pit Box” of Red Bull, the F1holzhaus (Literally, “the wooden house”). It premiered at the 2019 Spain Grand Prix and is since then the “home” of the team in Europe. Each Grand Prix, fourteen workers assemble their 1 221 square meters in just 32 hours (and disassemble them in less than a day).

This building reflects a change in the conception of construction, which now inevitably bets on sustainable buildings, capable of adapting, modifying and reusing.

Construction waste

The construction industry is one of the largest waste generators: some 2 200 million tons annually globally. In Europe, about 450 million tons, 40 % of all waste.

More than 90 % of the waste comes from demolitions, but those generated in work should not be forgotten (overwhelming or broken materials) and those that occur during manufacturing. The latter go unnoticed, but here it has a fact: the wooden beams that we can see in a building are only 20 % of the original wood. Up to 80 % has stayed on the road from the forest as production waste (Serrín, retales, discarded parts …).

This scenario reveals the limits of the linear model – manufacture, use, discard – that still dominates. To counteract it, the circular economy proposes design for Disassembly as a strategy. It replaces demolition by systematic disassembly, which allows Recover and revalue components.

This paradigm shift (to “use, throw” to “use, reuse, recycle”), already present in other areas, begins its journey in construction through various worldwide initiatives that seek to integrate these concepts in buildings of the safest, sustainable and durable future. They are the sample of how to achieve it from a conscious design, based on concepts such as modularity and standardization. To this is joined by a Proper Reversible Unions Designwhich allow to disassemble without damaging (and therefore, facilitate reuse) and digital tools already available such as “Material passports”digital documents that locate and quantify the products and materials of the building, which will greatly simplify its future reuse.

Read more: Do not we have enough buildings? The challenge of taking better advantage of the current

Of waste to construction materials

But, obviously, the solution is not just to disassemble and reuse what has already been built. In this change of model, of the linear when circular, it is also crucial to transform waste into resources. It is about overcoming the Cascadingthe traditional “recycling”, in which They are reused in lower value products (As an example, wood waste crushed to make panels). In contrast, the UPCyCling It proposes that already discarded materials have a new life as elements of greater value or utility.

Read more: Recycled jeans for the acoustic and thermal insulation of buildings

There are already concrete ideas to apply the UPCyCling Under construction. As we have seen, almost all its waste comes from demolition. But what if that construction garbage Not going to the landfill? What if it served to make a new building? That is the work and exploration area of the Spanish designer Lucas Muñoz. Observe the furniture and restaurant lamps Mo of movement or of space Sancal Colab (both in Madrid) and think how they can be made, from what materials. Do you guess? Everything is manufactured with the waste from the previous premises.

It is also necessary to act in production waste (remember that 80 % of wood that is lost on the way of the wood from the forest to the building). As an example, the Prisma project It is an initiative that proposes the manufacture of high -value added products, such as construction blocks (wood bricks) from the leftover waste of sawmills that, otherwise, would go to energy production (would be burned) or panel manufacturing.

As we have already said, thanks to UPCyCling The residue becomes a greater value. For this it is necessary to look for new imaginative solutions. Build a building with PET plastic soda bottles? Said and done: Look at the facade of Ecoark in Taiwanbuilt fitting them. And of course, the building is also entirely removable.

The Ecoark building in Taiwan, built as the headquarters of the International Flora of Taipei exhibition, is the first building in the world built with garbage, more than 1.5 million PET plastic bottles.