Guadalajara, Jal. The accelerated growth of data centers and artificial intelligence (AI) is beginning to put pressure on the global supply chain of electronic components, with risks similar to those experienced after the pandemic, warned the American Chamber of Commerce (AMCHAM) Guadalajara chapter.

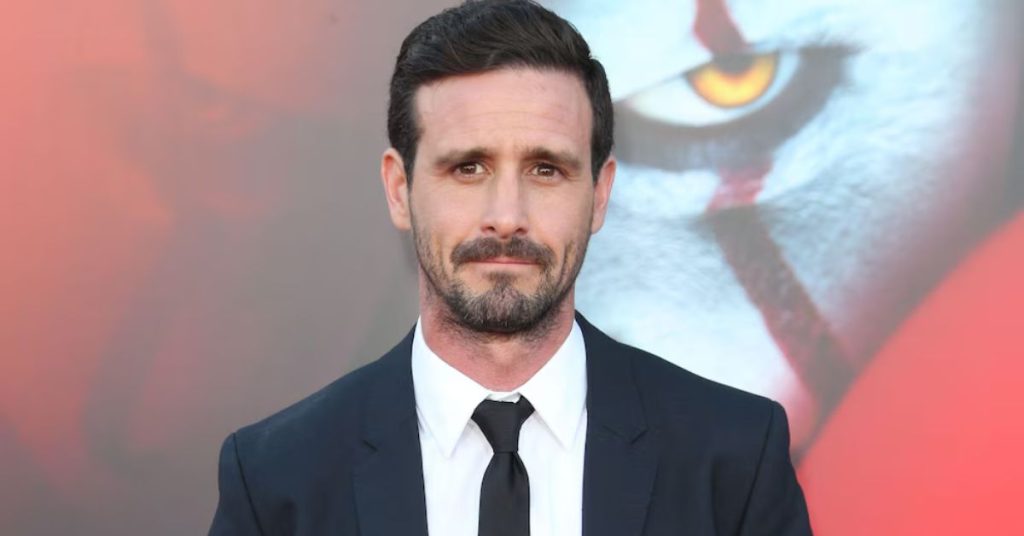

Its president, Ernesto Sánchez Proal, told El Economista that during the most recent meeting of the Council of Large American Companies of AMCHAM Guadalajara chapter, executives of US companies with operations in Jalisco agreed to light a “yellow light” in the face of the accelerated consumption of technological inputs necessary to operate large data centers and AI servers.

He explained that while the debate on artificial intelligence usually focuses on its impact on employment, there is a less visible but potentially more disruptive implication: the pressure on the ability to supply electronic components to different industries globally.

“This accelerated growth is implying the acquisition of electronic components on a very large scale. So, just as there was a shortage of electronic components in the post-pandemic that affected other industries such as the automotive industry, this effect is beginning to occur due to the components that are being used to build these servers and large data centers that have to do with making artificial intelligence work. This is said by executives of technology companies,” emphasized Sánchez Proal.

According to the president of AMCHAM Guadalajara chapter, the most in-demand components include memories and electronic cards, that is, printed circuits. However, processors and passive components could also be involved, inputs present in practically all industries.

Regional benefit

Sánchez Proal highlighted that, at a regional level, the phenomenon could have a positive effect for Jalisco, where numerous American companies dedicated to electronic manufacturing operate. However, he insisted, there could also be an impact due to the shortage of components, particularly in electronics-intensive sectors such as automotive, home appliances, and consumer electronics.

“Many of the American companies that are here in Guadalajara in that sector are already manufacturing components related to artificial intelligence, they are manufacturing equipment that has to do with this, data processors, etc. On that side, the regional effect is going to be positive in many of these companies, but there could be a negative effect in other sectors due to this shortage of components that is being projected given this boom,” he pointed out.

They take forecasts

Faced with this scenario, some companies are already adjusting their supply strategies, reinforcing advance purchases and inventories to mitigate possible disruptions. However, the president of AMCHAM Guadalajara acknowledged that completely avoiding a shortage will be difficult in the most critical components.

“I believe that in the specific components of this, it will be difficult to avoid some shortage effect; however, it could be reduced by adapting the designs to components that are not part of the supply chain of these large data and artificial intelligence centers.”

The evolution of the phenomenon will be one of the topics to be addressed during the next meeting of the Council of Large American Business, scheduled for February or March, when it is expected to have more information on the real pressure on the supply chain.