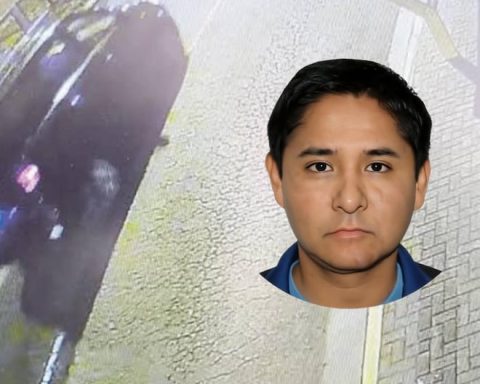

Monterrey, NL. Before the pause in the application of tariffs to Mexico it is necessary that companies of Nuevo León And from the country they make decisions about more slender practices and continuous improvement, this will allow them to have 20% more in their productivity, he told El Economista, César Palomar, CEO of Go Productivity, dedicated to training and certification with Lean methods.

In order to identify where the headaches are in the production lines, for example, you must go step by step, training talent in digital or technological issues.

“Large companies vs. small ones, they put money to automation, training, machinery, to be more efficient. For example, the Japanese have the 5S method: classification, order, cleanliness, standardization and discipline,” he said.

“We have to make more focus of how much it occurs but at what cost, with what efficiency and quality. If the tariffs come, we must prepare from efficiency, I am not saying that it will solve it but it will help them,” projection.

An example, he said, is that when working in a workshop or factory, and certain tool or elements is needed with which there is work and there is no order is delayed the operation. On the contrary, with the 5S method, time is reduced by up to 20%. That is, if 100 pieces are produced, applying these concepts, 120 pieces are manufactured.

Nuevo León maintains “operational discipline”

In the opinion of César Palomar, Nuevo León is above the national average in terms of reading methods, throughout the industry And it is considered one of the strong states of the north of the country, because due to its geographical location and the climate, in this region it is necessary to be more efficient.

The consultant commented that he works in Monterrey with an AAA company with presence in Latin America and that he has a “positive efficiency.”

“If you ask me, Nuevo León has everything precisely to be above the average. The key to continuing to grow and evolve is the operational discipline, this is what I call it,” he said.

Improve productivity

On the other hand, he explained that in Latin America 18 out of 20 companies have measurement problems to determine their current situation, what is delivered, with what quality, at what time, it is necessary to have a control board.

“When a process is well defined, this represents a 25% improvement in Time Market,” either in the automotive and retail sector, for example, he said.

In sum, there are things that do not require technological automation, but the implementation of a methodology “to know you as a company, know what your pain points are, what is the current situation and based on this, implement a practice as a process improvement, A control board and train collaborators, “César Palomar suggested.

RRG